Presenting the most exquisite and diverse creations of ice creams, açaí, and confectionery creams - perfected with state-of-the-art technology. Enriched by more than a decade of dedicated research and development, this innovation redefines excellence, empowering ice cream and pastry businesses to reach beyond the ordinary and achieve new heights of profitability. With intelligent operation, flawless compliance with international sanitary standards, remarkable energy efficiency, and accessible maintenance, it ensures success with confidence. Distinguished by exceptional product quality, unmatched versatility and a striking design worthy of display, it captivates customers and drives extraordinary sales growth.

Now, we unveil the details of this groundbreaking revelation set to inspire the global market:

1- Finatronic is the electronics embedded in the equipment, 100% proprietary and focused on the ice cream production process, prepared for artificial intelligence, connectivity, maintenance diagnostics and other features that visibly increase gains in the day-to-day work. Reliability, robustness and safety of operation, with state-of-the-art digital technology.

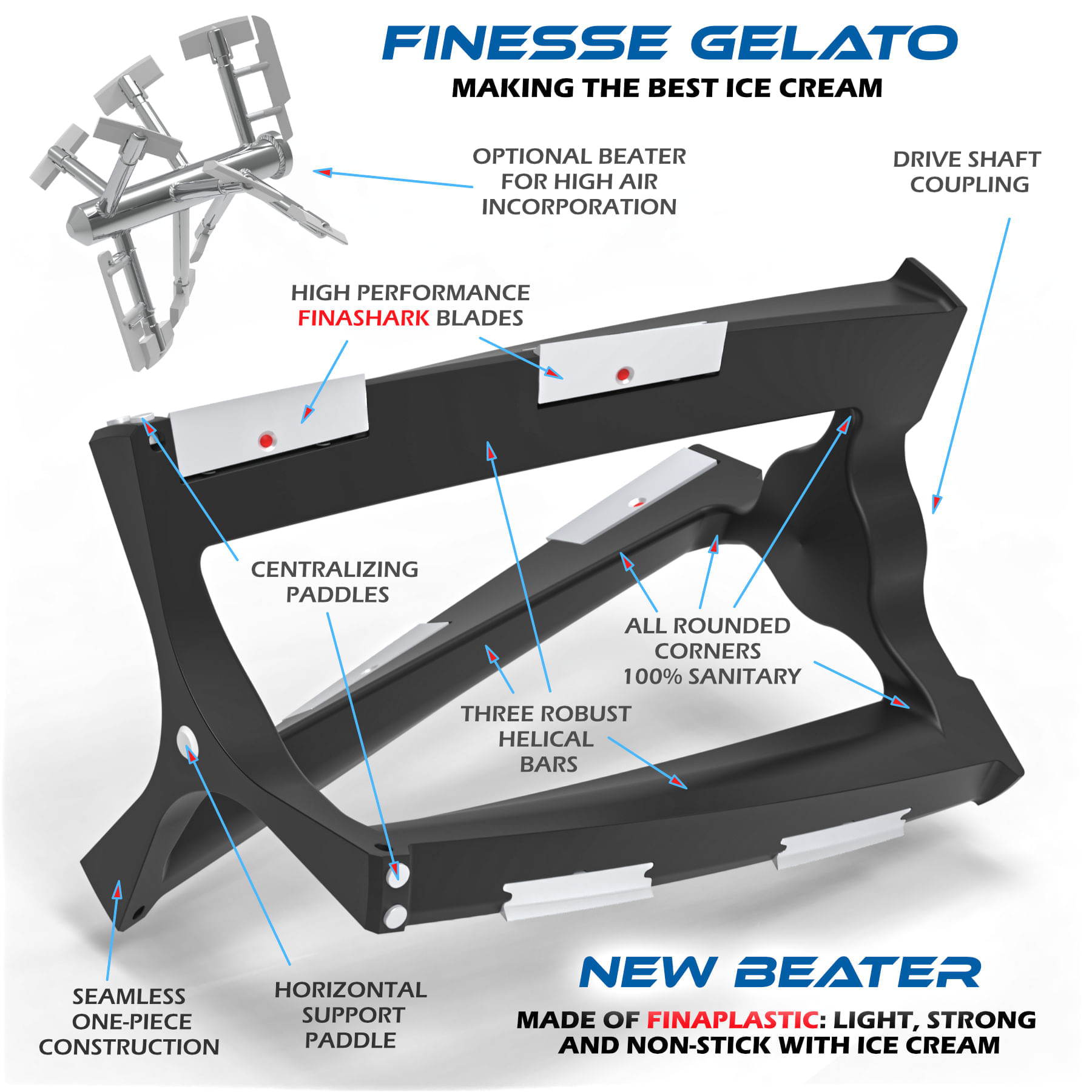

2- FinaPlastic is a certified plastics manufacturing process, exclusive of Finamac, starting from selected components that result in material that is inert to contact with food and the human body, very light, with high mechanical resistance, high resistance to heat and cold, high thermal insulation and low adhesion to ice cream. The process allows the manufacture of complex parts in a single body, without seams and without sharp corners, a technology similar to that used in the aerospace industry. The culmination of many years of engineering research devoted to the creation of high-quality ice cream.

3- FinaShark (Softening Hardness Aided by Rotating Knurling) is an ice cream scraping process based on the cutting power of shark teeth, which provides a 30% reduction in the effort of the electric motor that moves the beater/scraper, in addition to drastically reducing the size of the ice crystals formed, resulting in much creamier ice cream, stable and durable. Blades made of special plastic supported on springs, easy disassemble and clean. Does not retain ice cream or release harmful residues.

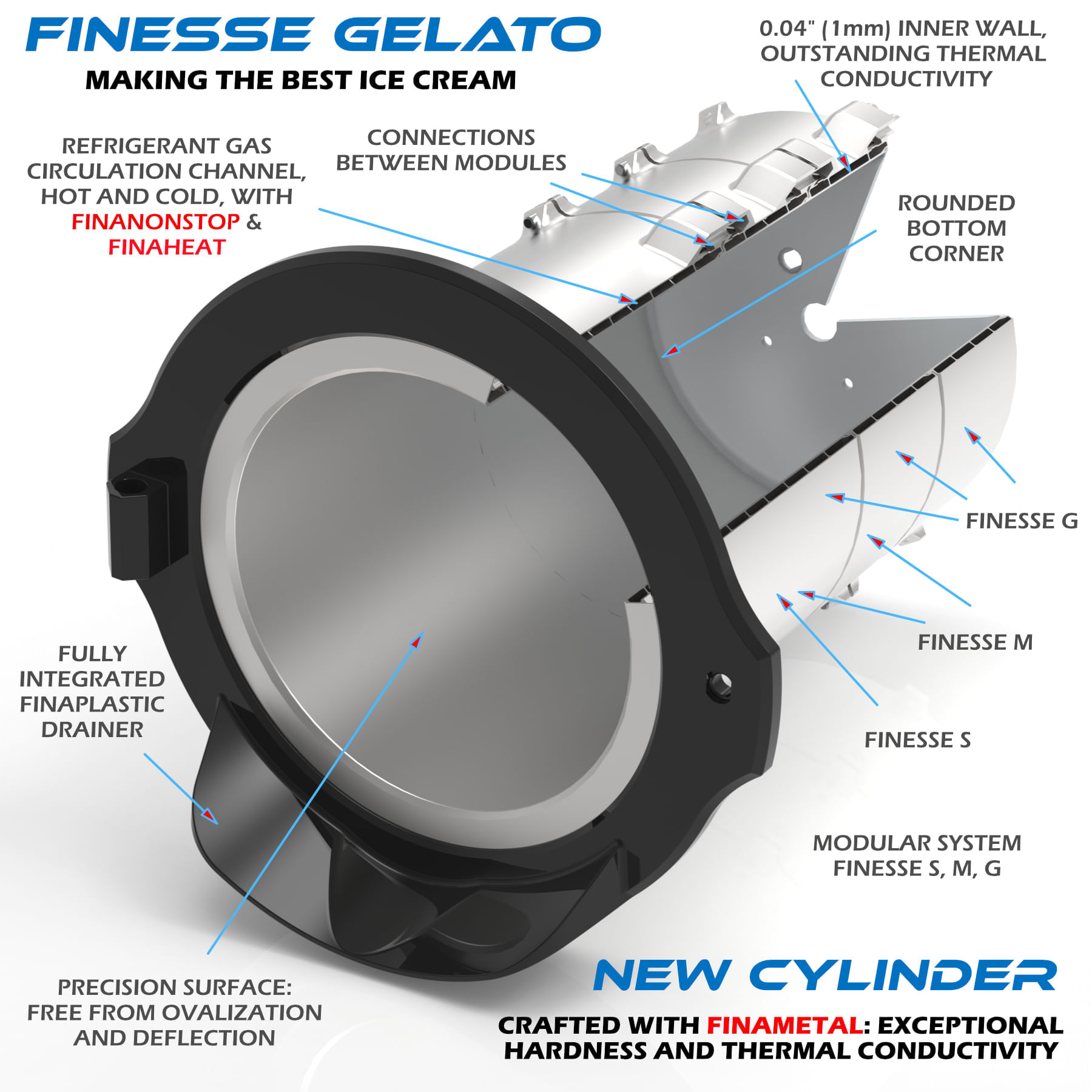

4- FinaMetal is a technology used by Finamac to produce highly complex sanitary metal parts, similar to those used in the aerospace industry, also the result of many years of research in the sector. High thermal conduction, higher production speed, higher profitability. Supports high and low temperatures, for heating and freezing various products.

5- FinaCoat is a technology used by Finamac for composite materials (fibers) in contact with food, approved by the American FDA. It allows the use of different colors, which match the architectural design of the business.

6- Finanonstop is an exclusive freezing system that allows you to place one mixture after another into the beater cylinder, without turning the equipment off and on again, which works continuously and considerably speeds up the production process: greater profitability.

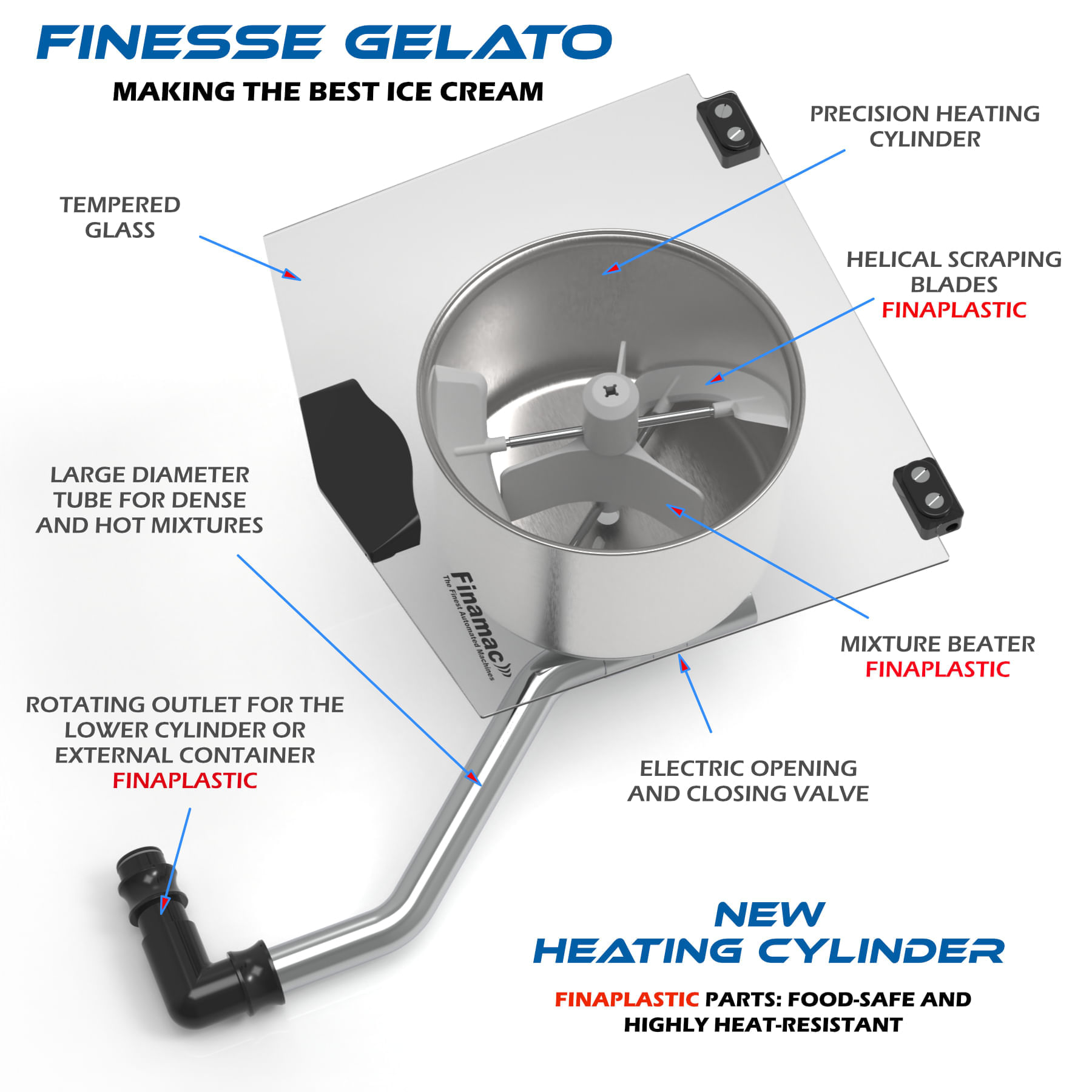

7- Finaheat is a thermal system to heat the cylinder where the ice cream is beaten, allowing a single cylinder to serve as a mixture pasteurizer, with subsequent freezing, or produce confectionery creams of various types. Low investment.

1 - Super creamy, soft and sandyness-free ice cream. New Panel.

IMPORTANT GAINS IN BUSINESS - Intelligent control of ice cream consistency ensures a higher percentage of frozen water and smaller ice crystals - delivering extraordinary quality that strongly appeals to consumers. No need to enter volume, mixture type, or additional settings - saving valuable time. Featuring a wide tempered front glass, fully washable surface and a 10” high-resolution touch display with extensive connectivity, operation, and maintenance functions. Powered by finatronic hardware and software, engineered exclusively for professional ice cream production.

COMMON MACHINES: DISADVANTAGES - Imprecise hardness control, with no intelligent system: grainy ice cream that drives customers away. Requires manual input of ice cream type, volume, consistency, and other parameters. Relies on generic commercial controllers not designed for ice cream. Outfitted with a low-durability plastic panel, non-washable surface, and mechanical buttons that easily oxidize.

2 - Next-Level Smoothness. Next-Level Consistency. The Secret to Perfect Ice Cream: The New Beater.

IMPORTANT GAINS IN BUSINESS - Robust FinaPlastic arms with rounded edges, metal-drive shaft coupling, centering pads, and the exclusive FinaShark blade system: delivering dry, consistent ice cream, ready to serve. Lightweight, durable, exceptionally easy to clean and non-stick. Cost-effective. Optional beater for air incorporation up to 70%, already proven in the market with Finamac PRO-4 and PRO-16 machines.

COMMON MACHINES: DISADVANTAGES - Twisted metallic design with multiple non-sanitary welds; extremely heavy (posing risk of injury if dropped); awkward handling; ice cream sticks to the surface; non-sanitary blades that are hard to clean; very high cost. Some models use metal blades and hard-chrome plating inside the cylinder - a practice that may release hazardous residues into the ice cream.

3 - Solid Ingredient Insertion, Multi-Format Extraction, Cup Dosing. New Front Door.

IMPORTANT GAINS IN BUSINESS - Insulating, light, resistant and very easy to remove; wide funnel with rounded corners and lid with closing palette; wide ice cream outlet, without threads and easy to disassemble; protective railings with different shapes; Optional dispenser for cups; gasket with 4 seats and eccentric latch attached to the door. Low cost, made of FinaPlastic.

COMMON MACHINES: DISADVANTAGES - Machined metal, with welds and threads, very heavy (it can hurt the operator if it falls), clumsy, adheres ice cream, does not insulate thermally, drips water on the ice cream, small funnel with sharp corners, fixed safety grids with a single shape, latch attached to the machine, gasket that requires a lot of tightening to seal, high cost.

4 - Total hygiene. New Drainer.

IMPORTANT GAINS IN BUSINESS - Light and resistant, rounded corners, 100% sanitary, it fully embraces the cylinder and houses the door hinge, in a single piece of FinaPlastic. Bottom part can be washed without any disassembly. Definitive and exclusive solution for draining ice cream/confectionery cream and cleaning water.

COMMON MACHINES: DISADVANTAGES - Made of sheet metal, often welded, fastened with screws or pins in front of the machine, does not meet sanitary standards, is a source of ice cream contamination. Requires disassembly for washing.

5 - Containers of any shape and size. New Pan Holder.

IMPORTANT GAINS IN BUSINESS - A single-piece design - ultra-light and highly durable. Multiple height adjustments with the option of motorized lift and lowering. Accommodates containers of every shape and size. Made of FinaPlastic, 100% hygienic.

COMMON MACHINES: DISADVANTAGES - Made from bent and welded metal sheets, fixed to the machine with pins or screws. Limited height adjustment, non-compliant with sanitary standards - a direct source of ice cream contamination.

6 - Unparalleled ultra-fast freezing and heating. New Horizontal Cylinder.

IMPORTANT GAINS IN BUSINESS - Integral FinaMetal construction, no welds, high hardness stainless material, does not wear, 1mm thickness only, super thermal conduction, freezes in a few minutes. Heats up mixes quickly with FINAHEAT. Beater drive shaft inside the cylinder (No. 4, above), total hygiene. It uses FINANONSTOP to speed up production. Easily dismantled from the front of the machine. 100% sanitary assembly. Wide diameter of 10.6” (269mm).

COMMON MACHINES: DISADVANTAGES - Many welded parts, wall thickness up to 4mm, low thermal conduction, low hardness and wearable steel. No heating option. Beater drive shaft outside the cylinder, no hygiene. Difficult disassembly from the inside of the equipment. Forms sharp corner with the front plate of the machine, with exposed screws. Does not meet sanitary standards. Small diameter, 7.9” (200mm) or a little more, hinders production.

7 - Confectionery and Gelato. New Heater Cylinder.

IMPORTANT GAINS IN BUSINESS - Precise heating for confectionery creams and gelato; high-efficiency mixer made of FinaPlastic; tempered glass lid with condensed water drainage; electric valve for draining mixtures; connection for lower cylinder in FinaPlastic, does not burn the operator's hand and rotates to fill external containers; various heating programs, for numerous creams.

COMMON MACHINES: DISADVANTAGES - Stainless steel mixer with welds, very heavy and unsanitary; inaccurate heating often burns the mixture; not very versatile mixture outlet, made of metal, burns the operator's hand; easily scratchable plastic lid, ends up becoming opaque over time; condensed water drips into the cylinder, altering the quality of the mixture and the final product.

8 - Formula 1 technology structure. New Housing.

IMPORTANT GAINS IN BUSINESS - Trusted by aviation and Formula 1 engineering, the housing is built from high-resistance fiber with smooth and seamless curves, impossible to achieve with stainless steel. Its aerodynamic airflow ensures efficient cooling. The machine is 40% lighter and available in multiple colors to match your décor. Components are easily replaceable. Food-contact areas are made with FinaCoat. Fully washable and designed to attract consumers when on display - driving significant sales growth.

COMMON MACHINES: DISADVANTAGES - Ugly box-shaped stainless-steel housings with welded mild steel structures are prone to corrosion. Sharp edges, exposed welds and visible screws make them unaesthetic and unhygienic. With no aerodynamic airflow, cooling efficiency is compromised. Overly heavy, hard to move and costly to transport. Built with non-replaceable parts and non-washable surfaces, they are often hidden from customers due to their lack of appeal and hygiene.

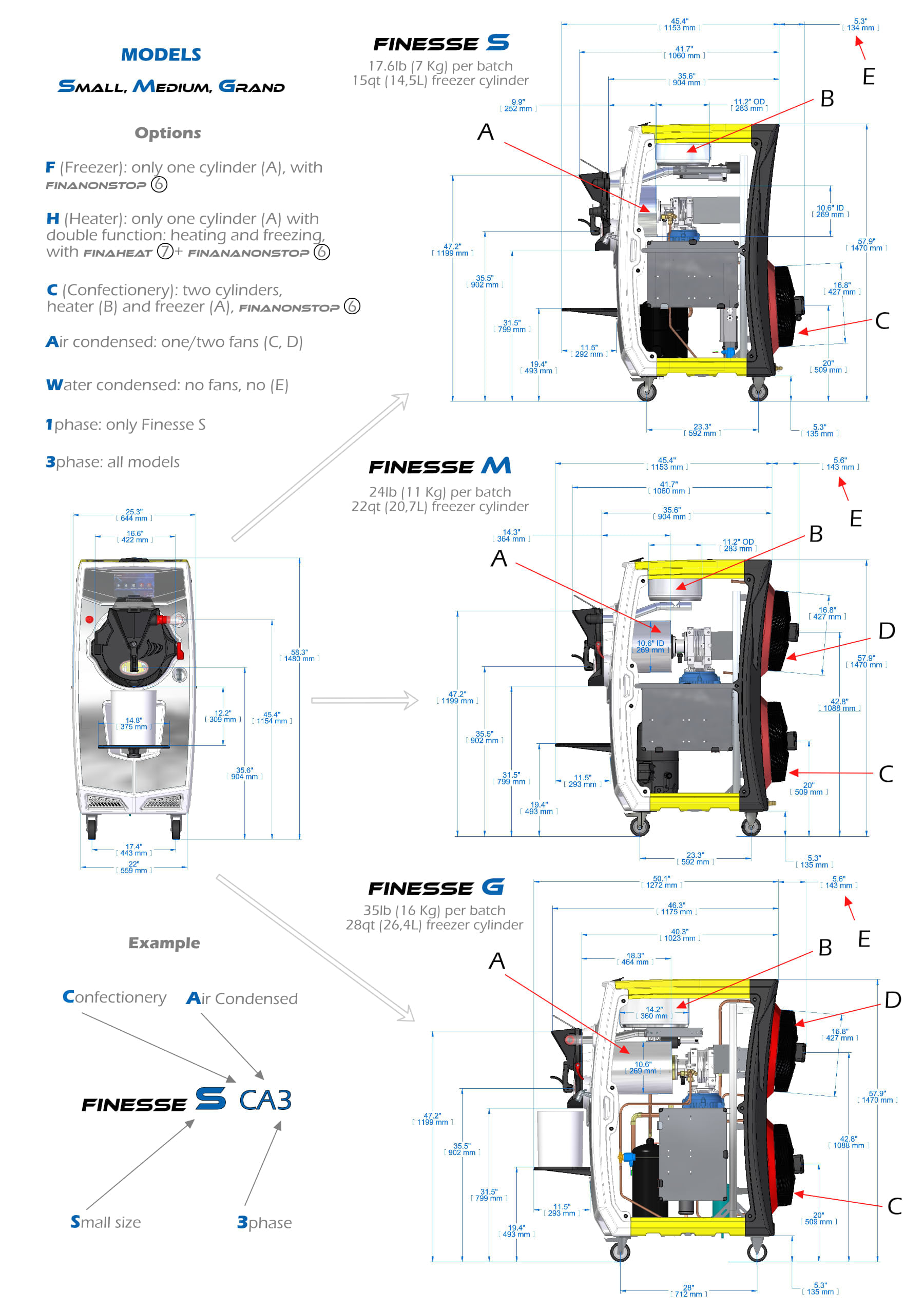

Finesse Line - Premium Ice Cream and Gelato Making Machine

People also bought

BRAZIL - Sales

Avenida Nazaré, 1657 - Ipiranga

CEP: 04263-200 - São Paulo / SP

Phone: +55 11 2135 6500

USA & World - Sales

11231 NW 20th Street Unit 130

ZIP: 33172 - Miami / FL

Phone: +1-786-408-0729