What is instant ice cream? It is the ice cream whipped and frozen on the spot, in the exact dosage to be served. It is not ice cream taken from a container inside a freezer, nor ice cream taken from a soft serve machine type, which is spinning all day inside a freezer cylinder, as in the machines used by fast food chains, for example.

Instant ice cream is made by dosing the liquid mixture, in the measure of a cone or cup, inside a beater/freezer cylinder, and extracted 100% from this cylinder in 20 seconds, resulting in an extraordinarily creamy product, without any feeling of sandiness, very common in ice creams that are stored in freezers or soft serve machines.

This rapid freezing capability makes it possible to produce gelatin-based ice cream, known in some countries as American ice cream or "childhood flavor" ice cream, as well as milk or water-based ice cream of various formulations, including gelato, as well as frozen yogurt, açaí, cold drinks, milkshakes, slushies and several other types of freshly beaten and frozen desserts, with unsurpassed quality.

If instant ice cream is the best of all, because it is frozen and served on the spot, why aren't all machines like that? Because each ice cream needs 15 to 30 seconds to be produced, which makes it difficult to serve customers in high-traffic places. In such cases, it is necessary to use freezers with ready-to-serve ice cream stock, or soft serve machines, which keep a certain amount of ice cream churning - typically 2 to 3 liters - inside one or two freezing cylinders.

See below the innovations implemented in this machine, which will surprise the global ice cream market:

1- FinaPlastic is a certified plastics manufacturing process, exclusive of Finamac, starting from selected components that result in material that is inert to contact with food and the human body, very light, with high mechanical resistance, high resistance to heat and cold, high thermal insulation and low adhesion to ice cream. The process allows the manufacture of complex parts in a single body, without seams and without sharp corners, a technology similar to that used in the aerospace industry. The culmination of many years of engineering research devoted to the creation of high-quality ice cream.

2- FinaShark (Softening Hardness Aided by Rotating Knurling) is an ice cream scraping process based on the cutting power of shark teeth, which provides a 30% reduction in the effort of the electric motor that moves the beater/scraper, in addition to drastically reducing the size of the ice crystals formed, resulting in much creamier ice cream, stable and durable. Blades made of special plastic, designed for easy disassembly and cleaning. They do not retain ice cream or release harmful residues.

3- FinaMetal is a technology used by Finamac to produce highly complex sanitary metal parts, similar to that used in the aerospace industry, also the result of many years of research in the sector. High thermal conduction, higher production speed, higher profitability. Supports high and low temperatures, for heating and freezing various products.

4- FinaCoat is a technology used by Finamac for composite materials (fibers) in contact with food, approved by the American FDA. It allows the use of different colors, which match the architectural design of the business.

5- Finaflavor are ready-to-use mixes for producing gelato or milk-based ice creams in a variety of flavors. They deliver maximum overrun, smooth texture, and extended shelf life, ensuring the highest profitability from the machine.

1 - A remarkable variety of products, delivered by a single machine.

IMPORTANT GAINS IN BUSINESS - The only one capable of making gelatin ice cream, an essential substance to strengthen bones and joints, reduce skin sagging, delay aging, reduce the formation of wrinkles and expression lines, prevent the formation of cellulite, strengthen nails, increase hair growth and shine, increase the feeling of satiety and several other nutritional advantages. In addition to gelatin, the machine produces regular ice cream, premium ice cream, açaí, gelato and others, with the highest level of quality ever seen, always instantly. To maximize profit and performance, use finaflavor ingredients.

COMMON MACHINES: DISADVANTAGES - The few machines that produce gelatin ice cream are not sanitary-approved and release metal residues on the product; other machines produce soft ice cream in only two flavors, but it is not instant ice cream.

2 - Customer-Magnet Machine, with a striking visual appeal.

IMPORTANT GAINS IN BUSINESS - We eat with our eyes first - that’s why it’s essential for the machine to spark consumer desire. With a wide range of colors and an ultra-modern design, it seamlessly adapts to any brand identity, ensuring guaranteed commercial success.

COMMON MACHINES: DISADVANTAGES - They offer no visual appeal; on the contrary, they appear inelegant, lacking in hygiene, and often uninviting due to their absence of presence.

3 - Flavor selection and precise product volume dosing.

IMPORTANT GAINS IN BUSINESS - Each pin controls the selected flavor; once opened, the flavor is drawn by the dosing piston as the handle is lifted. When lowered, the flavor is released into the mixing/freezing cylinder at the desired volume. This ensures serving consistency and repeatability, boosting product yield and enhancing business profitability.

COMMON MACHINES: DISADVANTAGES - No machine offers portion control for ice cream; all rely entirely on the operator’s skill. It is very difficult to verify how many servings were actually sold at the end of the day. Flavor changes are neither hygienic nor simple.

4 - Flavors on Display, Customers on the Way.

IMPORTANT GAINS IN BUSINESS - The vibrant colors of the flavors attract customers, and the transparent tank lid enhances this appeal. Plus, it’s designed for effortless disassembly and cleaning - 100% hygienic.

COMMON MACHINES: DISADVANTAGES - No other machine offers true flavor visibility - they remain hidden inside tanks. Some use upside-down glass or plastic bottles to display flavors, a solution that is neither aesthetic nor hygienic.

5 - Milk-based flavors can be preserved in the tanks.

IMPORTANT GAINS IN BUSINESS - Refrigerated tanks are essential to preserve the ingredients that will be transformed into instant ice cream. A high-efficiency cooling system maintains a stable 4°C and prevents ice formation inside the tanks. This ensures the machine can operate even in hot, high-traffic outdoor locations - boosting business profitability.

COMMON MACHINES: DISADVANTAGES - Conventional machines lack refrigerated tanks, limiting production to gelatin-based ice cream. Machines that do feature refrigerated tanks often suffer from ice build-up inside, which melts into the mix and compromises product quality.

6 - Unmatched creaminess. Perfect consistency. High aeration.

IMPORTANT GAINS IN BUSINESS - Instant ice cream beating and freezing is a complex science. The exclusive finashark blade technology ensures maximum aeration and ultra-fine ice crystals, delivering an ice cream like no other - a quality customers instantly notice and keep coming back for!

COMMON MACHINES: DISADVANTAGES - They use imprecise metal or plastic scrapers, resulting in ice cream with poor aeration and a gritty texture. Moreover, they are not sanitary approved.

7 - Cabinet with Formula 1 technology.

IMPORTANT GAINS IN BUSINESS - Used in aircrafts and race cars, the cabinet is built from high-resistance fiber, with seamless curves impossible to achieve with stainless steel sheets. Its aerodynamic airflow ensures efficient cooling. The machine is 40% lighter, available in multiple colors to match your décor, and designed with easily replaceable parts. Equipped with FinaCoat in all food-contact areas, it is fully washable. When showcased, it attracts customers and drives sales.

COMMON MACHINES: DISADVANTAGES - Ugly box-shaped stainless-steel cabinets with welded mild steel structures are prone to corrosion. Sharp edges, exposed welds and visible screws make them unaesthetic and unhygienic. With no aerodynamic airflow, cooling efficiency is compromised. Overly heavy, hard to move and costly to transport. Built with non-replaceable parts and non-washable surfaces, they are often hidden from customers due to their lack of appeal and hygiene.

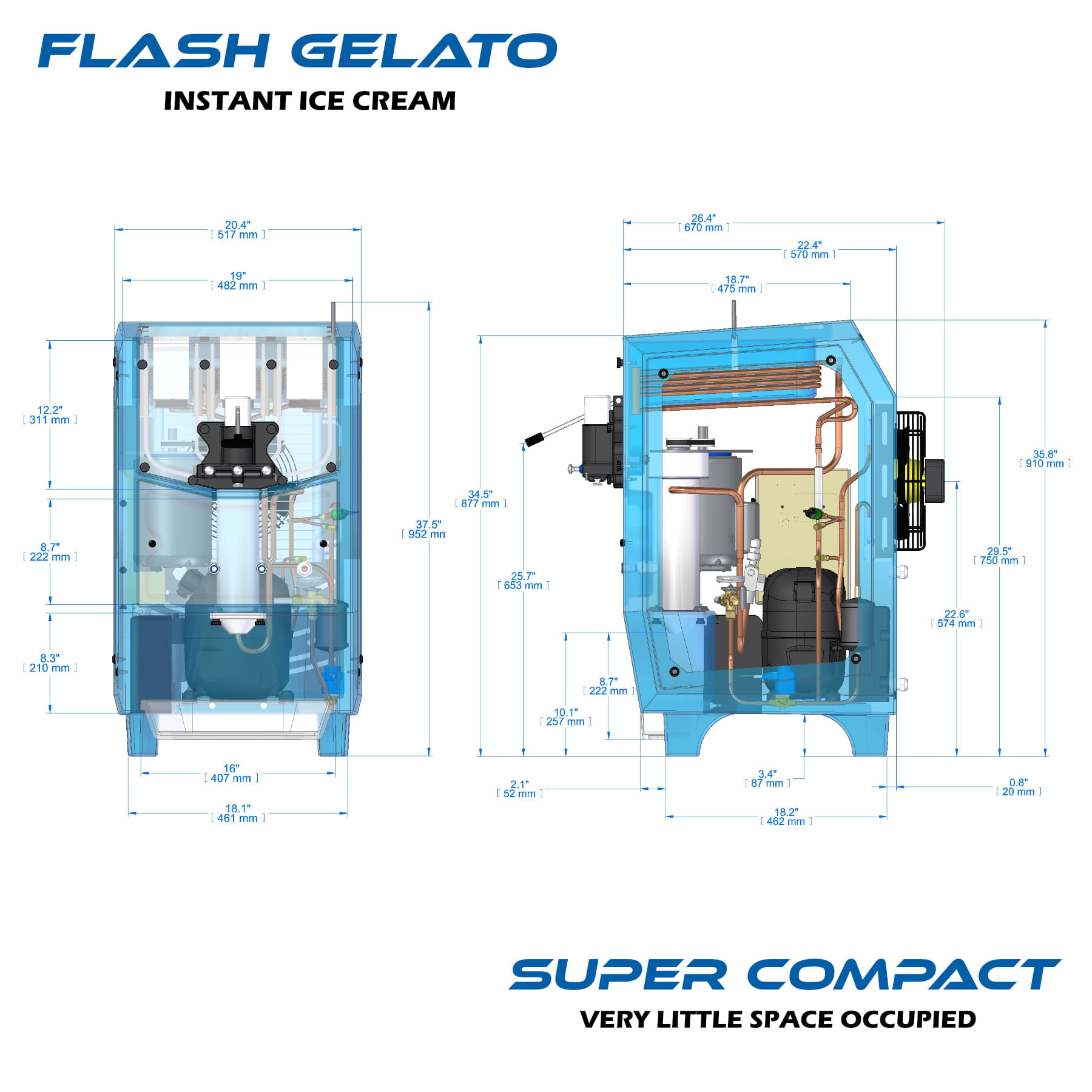

8 - Small footprint, reduced cost.

IMPORTANT GAINS IN BUSINESS - Space is expensive - that’s why our equipment is compact. Easy to place anywhere, simple to move or transport. Runs on low-consumption single-phase power. Perfect for convenience stores, food trucks, cafés, bakeries, dessert shops, restaurants, and fast-food chains.

COMMON MACHINES: DISADVANTAGES - They take up valuable space due to their large dimensions. Excessive weight makes transport and handling difficult. Installation is limited, as they usually require three-phase electrical power.

Flash - Instant Fresh Ice Cream

People also bought

BRAZIL - Sales

Avenida Nazaré, 1657 - Ipiranga

CEP: 04263-200 - São Paulo / SP

Phone: +55 11 2135 6500

USA & World - Sales

11231 NW 20th Street Unit 130

ZIP: 33172 - Miami / FL

Phone: +1-786-408-0729