*This machine is not certified by ETL/UL/NSF rules.

*Please check the laws in your country about food preparation before finish your purchase.

PRODUCTION: 4000 to 6000 ice pops/h*

*Production depends on the climatic conditions of the location where the machine is installed.

Automatic dosage of the popsicle moulds (optional).

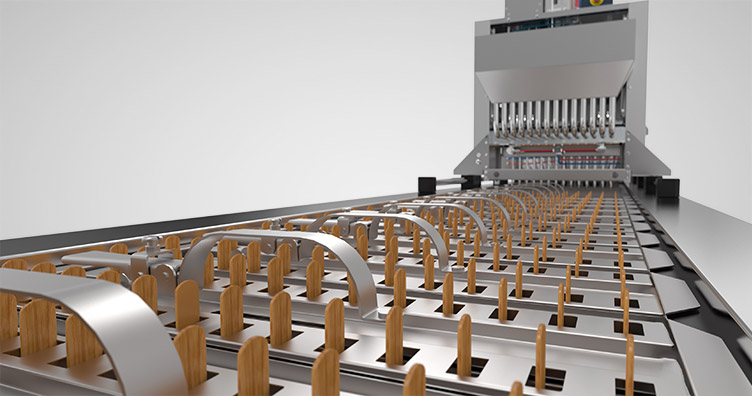

Automatic system for extraction and movement of the moulds.

It`s the unique equipment that requires only 30 moulds of 28 popsicles cavities each to work and reaches the production of up to 6000 popsicles / hour..

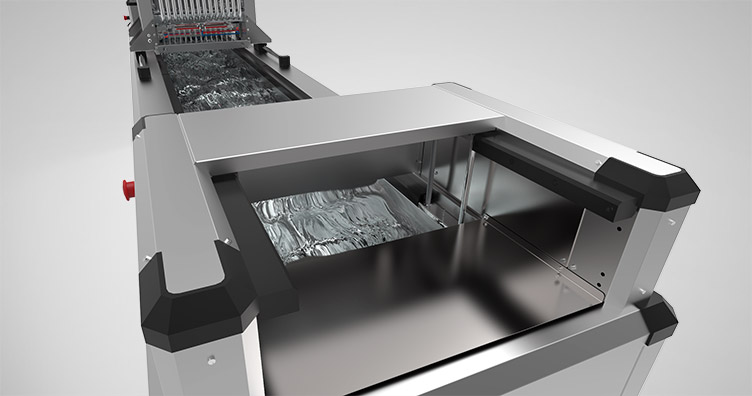

Agitation by pump.

Semi-hermetic compressor, low noise level, and high energy savings.

Equipped with rotary wheels in order to facilitate transportation, handling and cleaning.

Power supply: 220V or 380V, 3-phase, 50Hz or 60Hz.

Shell in Tube water condenser system.

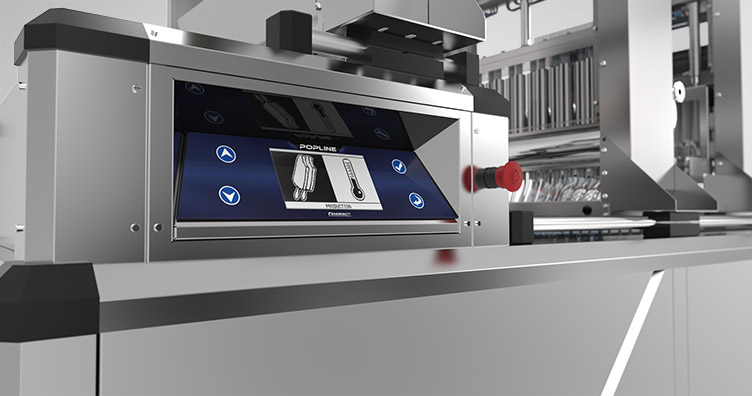

Popsicle production digitally displayed.

R 452 ecologic refrigeration gas.

Reduced maintenance costs.

Fluid Volume: 290 Liters / 76.61 gal.

Number of Forms: 30 Forms with 28 cavities in the tank and 02 in the entrance ramp.

Dosers: from 1 to 3 dosers.

Insertion and extraction of forms: Automated system.

**Measured production with 63ml / 0.02 gal mold, Brida model. For different volumes or formats the hourly production can vary. The production in 50Hz will have a reduction of up to 20%.

Water condensation equipment: requires a cooling tower.

When purchasing our products, we guarantee excellence in quality and support.

We provide after sales with qualified and dedicated specialists.

1. The best cost/benefit rate in the market.

2. Significant labor reduction, due to the optional automatic devices.

3. Easy to operate, install and transport.

4. Modular design allows production to increase or decrease, according to demand.

5. Occupies only 60% of the normal area used by a conventional equipment.

6. The latest technology in popsicle machines.

FinamacTM is the number 1 choice of pop stores in the USA, also providing technological solutions for ice cream, ice pops and frozen desserts, exporting machinery worldwide to more than 100 countries.